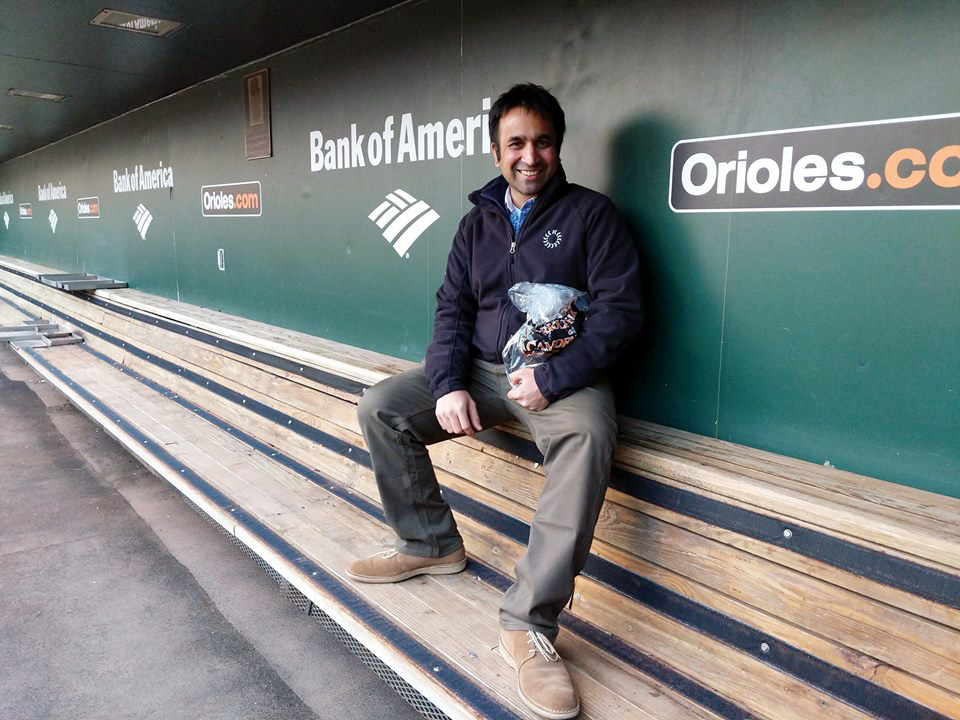

My first introduction to the BREP program was in the spring of 2001 as part of a campus tour for admitted high school seniors. I had declared my major of Chemical Engineering and a facility tour concluded in the Bioprocess Scale-Up Facility (BSF). I introduced myself to the facility’s manager, Ben Woodard, and asked if he was hiring any part-time undergrad lab assistants. Ben asked me to leave me some contact information and he would be in touch if anything became available. Ben followed up with me a few weeks later and asked if I would be interested in starting work at the BSF that summer. I could not have answered, “yes” any quicker. More importantly, I did not realize that Ben had just offered a position to me that would single-handedly open doors leading to the position I have today – leading the Gene Therapy Manufacturing Sciences Group at Biogen.--John Kerwin